Understanding Machine Vision: Applications, Benefits, and Future Trends

What is Machine Vision?

Definition and Overview of Machine Vision

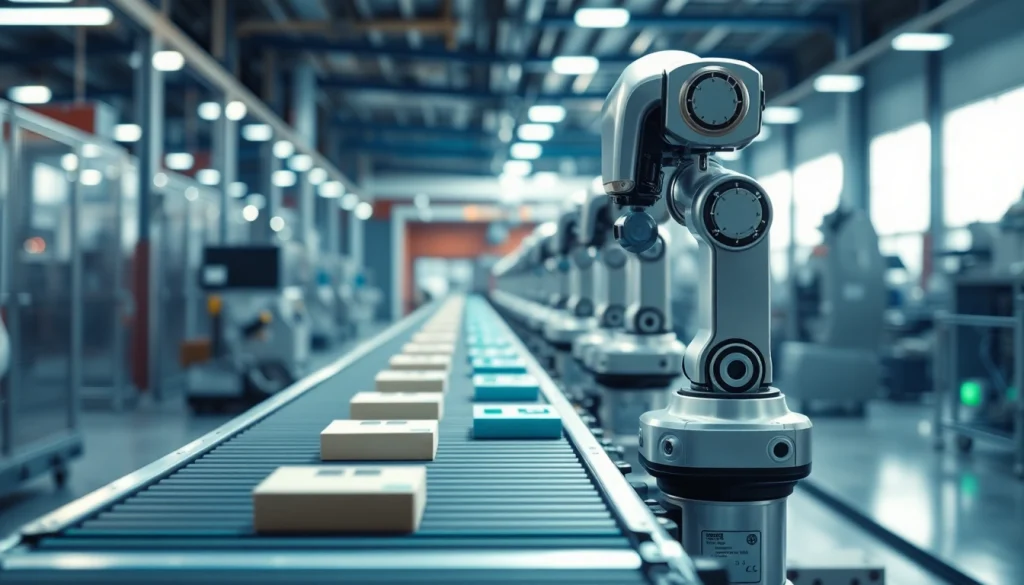

Machine vision refers to the technology and methods used to provide imaging-based automatic inspection and analysis. This innovative field plays a crucial role in industrial automation, enabling systems to interpret visual information and make decisions based on the data received from various imaging devices such as cameras and sensors. Specifically, machine vision systems incorporate powerful algorithms and artificial intelligence to automate processes that would typically require human visual confirmation, including quality control, object identification, and more.

History and Evolution of Machine Vision Technology

The roots of machine vision can be traced back to the early 1960s when researchers began experimenting with video technology and image processing techniques. Initially, machine vision systems were limited to simple tasks involving linear measurement and basic image recognition, often relying on low-resolution cameras and rudimentary processing capabilities. The rapid advancements in digital imaging technologies, combined with increasing computational power, have significantly enhanced the capabilities of machine vision systems. From the integration of artificial intelligence in the late 1990s to the emergence of deep learning-based algorithms in the 2010s, the evolution of machine vision has accelerated tremendously, broadening its application scope across various industries.

Key Components of Machine Vision Systems

A typical machine vision system consists of several integral components:

- Cameras: High-resolution cameras capture images of the objects in question. Different types include line scan or area scan cameras depending on the specific application.

- Lighting: Proper illumination is critical to ensure that the captured images are clear and of high quality, allowing for accurate analysis.

- Processing Unit: This includes hardware such as CPUs and GPUs that interpret the raw image data using sophisticated algorithms.

- Software: Algorithms and software processes analyze the images to determine characteristics, detect defects, or identify objects.

- Output Devices: These may include screens for monitoring or actuators for triggering actions based on analysis results.

Applications of Machine Vision in Industries

Manufacturing and Quality Control

In manufacturing, machine vision is utilized for a wide range of applications from inspection to verification tasks. Machine vision systems enable automated defect detection and inspection of goods on production lines, substantially reducing the need for manual quality control. For instance, in the electronics industry, machine vision is pivotal in inspecting circuit boards for defects like missing components or soldering errors that could compromise product quality.

Moreover, the use of machine vision in manufacturing allows for real-time monitoring of processes, ensuring a continuous quality assurance system. This results in increased product quality, reduced waste, and enhanced operational efficiency.

Healthcare and Medical Imaging

Machine vision is increasingly adopted in the healthcare sector, particularly in medical imaging technologies such as MRIs and CT scans. Advanced image processing helps radiologists to detect anomalies in images with improved accuracy and speed. With the assistance of machine vision, diagnostic processes can be expedited, allowing for quicker treatment decisions.

Furthermore, machine vision in healthcare can facilitate tasks like analyzing samples in laboratories, counting cells, or even identifying pathogens, thereby enhancing overall patient care.

Automotive Industry Innovations

The automotive sector has integrated machine vision technology for various applications, including assembly line automation, quality assurance, and autonomous vehicle navigation. Within manufacturing plants, machine vision systems help ensure that assembled parts meet stringent safety and quality specifications by inspecting components at various stages of production.

When it comes to autonomous vehicles, machine vision systems provide the situational awareness necessary for navigation and obstacle detection. These systems can interpret complex driving environments, identify road signs, and detect pedestrians, leading to advancements in smart transportation technology.

Comparing Machine Vision and Computer Vision

Fundamental Differences Between Machine Vision and Computer Vision

While machine vision is a subset of computer vision, it focuses primarily on industrial applications where visual inspection plays a vital role. Computer vision encompasses a broader spectrum of visual processing technologies, including machine learning techniques that enable systems to analyze and interpret images beyond the realm of industrial settings. For example, computer vision technologies are commonly employed in fields like security surveillance, facial recognition, and augmented reality.

Applications Specific to Each Domain

Machine vision specifically targets applications such as:

- Defect detection and classification

- Barcode and QR code reading

- Parts localization and identification in manufacturing

Conversely, computer vision is applied in:

- Facial recognition systems

- Autonomous vehicle navigation

- Healthcare diagnostics through image analysis

Future Trends and Intersections of Both Technologies

The intersection of machine vision and computer vision is increasingly prominent as the capabilities of AI improve. Future trends may see machine vision systems incorporating more advanced AI algorithms derived from computer vision research, enabling them to interpret more complex visual data and make decisions with greater accuracy. This integration could result in even more efficient manufacturing processes and improved outcomes in healthcare diagnostics.

Implementing Machine Vision: Best Practices

Choosing the Right Hardware and Software

When implementing machine vision, selecting the appropriate hardware and software is crucial for successful deployment. Factors such as image resolution, speed, and compatibility should be assessed to ensure optimal performance. It’s essential to thoroughly evaluate camera specifications, lighting conditions, and processing algorithms to align with the specific requirements of the application.

Integration with Existing Systems

Seamless integration of machine vision systems with existing production systems can significantly enhance operational efficiency. Identifying the right interfaces and communication protocols is vital in this process. Additionally, engaging with vendors who specialize in system integration can facilitate smoother transitions.

Addressing Common Challenges in Implementation

Common challenges encountered during the implementation of machine vision systems include lighting inconsistencies, camera positioning issues, and data processing bottlenecks. To mitigate these challenges, thorough planning and testing should be conducted prior to full-scale deployment. Continuous evaluation of system performance post-implementation also ensures that any arising issues can be promptly addressed.

Future Trends in Machine Vision

AI and Deep Learning in Machine Vision

The integration of AI and deep learning into machine vision holds the potential for transformative advancements in accuracy and efficiency. By utilizing neural networks to analyze visual data, machine vision systems can learn from vast datasets, enabling them to adapt to new patterns and improve over time. This not only enhances defect detection rates but also allows for predictive maintenance by identifying trends before failures occur.

Advancements in Imaging Technology

The field of imaging technology is constantly evolving, with trends showing a shift toward higher resolution sensors, improved imaging algorithms, and enhanced speed of data processing. Such advancements will make it feasible to implement machine vision in more complex operational environments, offering solutions that address previously unsolvable challenges.

Market Trends and Economic Impacts

As industries continue to see the benefits of implementing machine vision systems, the market for these solutions is predicted to grow significantly. This growth is driven by factors such as rising demand for automation, a greater focus on quality control, and advancements in imaging technologies. As businesses recognize the economic advantages associated with reducing errors, enhancing productivity, and improving quality assurance, the adoption of machine vision technology will likely accelerate.